Welcome to the R2-D2 Manual! This guide provides comprehensive instructions for assembling and operating your LEGO Star Wars R2-D2 model, ensuring a seamless and enjoyable experience.

1.1 Brief History of R2D2

R2-D2, the iconic astromech droid from the Star Wars universe, has become a cultural phenomenon. Created by Industrial Automaton, R2-D2 first appeared in Star Wars: Episode IV ⎯ A New Hope and has since played a pivotal role in the series. Known for his resourcefulness and loyalty, R2-D2 has inspired numerous toys, models, and replicas. The Hasbro R2-D2 and LEGO Star Wars R2-D2 kits allow fans to build and customize their own versions of this beloved droid, with detailed manuals guiding enthusiasts through assembly and operation.

1.2 Purpose of the Manual

This manual serves as a comprehensive guide for the assembly, operation, and customization of the R2-D2 model. It provides detailed step-by-step instructions, ensuring users can successfully build and utilize their droid. The manual covers basic operations, advanced features, and troubleshooting, making it an essential resource for both beginners and experienced enthusiasts. By following the guidelines, users can ensure optimal performance and longevity of their R2-D2 unit. This document is designed to be user-friendly, offering clear explanations and visual aids to enhance the overall experience.

Components and Parts of R2D2

The R2-D2 model includes a projector, remote control, stand, AC adapter, battery, lens cover, and instruction manual. Additional components like composite video inputs and connections are provided for functionality.

2.1 List of Included Components

- R2D2 Projector for displaying content.

- Millennium Falcon Remote Control and Stand for operation.

- AC Adapter (110-240V) for power supply.

- 7.2V NiCd Battery for cordless use.

- Lens Cover for protection.

- Instruction Manual (CD) for setup guidance.

- Composite Video Input and Connections for compatibility.

These components ensure a complete and functional R2D2 experience, tailored for both assembly and operation.

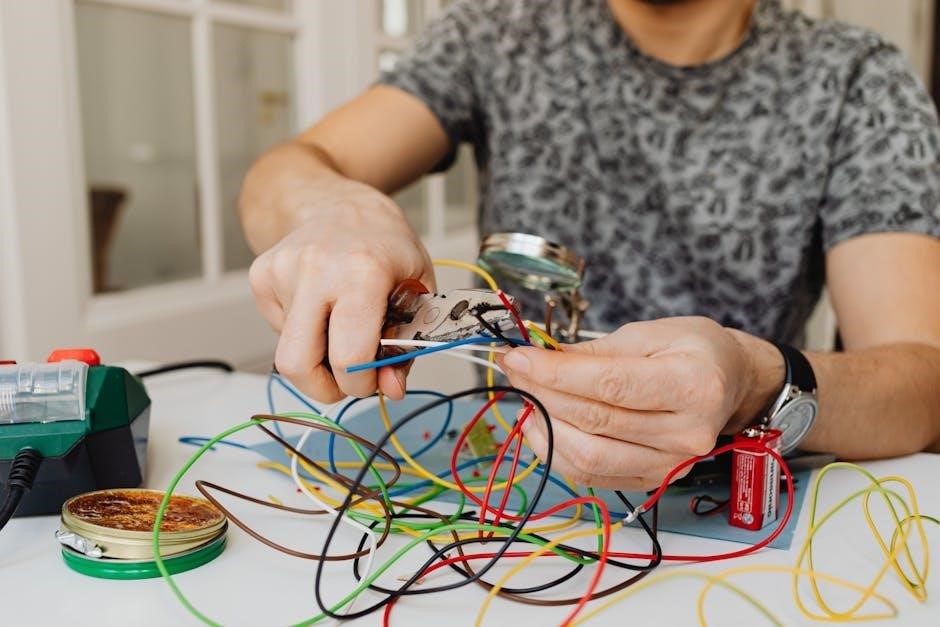

2.2 Additional Tools and Materials Needed

To complete the assembly of your R2D2, ensure you have the following tools and materials:

- Screwdrivers (flathead and Phillips) for securing parts.

- Pliers for gripping small components.

- Allen wrench for specific bolts.

- PDF reader to access digital instructions.

- Workbench or flat surface for assembly.

- Optional: Paint and brushes for customization.

These tools will aid in a smooth and efficient assembly process, ensuring all components fit together perfectly.

Assembly Instructions

Begin by gathering all tools and parts. Start with the base, attaching wheels and motors. Next, assemble the body panels and dome, ensuring alignment. Add internal mechanisms, then install the control panel. Finally, attach external details and test functionality. Follow the step-by-step guide for precise instructions.

3.1 Step-by-Step Assembly Guide

Start by assembling the base unit, attaching the wheels and motors. Next, align and secure the body panels to the frame. Install the dome mechanism, ensuring proper rotation. Attach the control panel and connect internal wiring. Follow the diagram to fit the exterior details, such as antennae and sensors. Refer to the included schematics for precise placement. Tighten all screws firmly but avoid over-tightening. Finally, test the mobility and functionality of the droid before moving to customization. Always refer to the provided diagrams for visual guidance.

3.2 Common Mistakes to Avoid During Assembly

One of the most common mistakes is rushing through the instructions without aligning parts properly. Ensure all components fit snugly before securing them. Avoid forcing pieces together, as this can damage the model. Misplacing small parts, such as sensors or antennae, can affect functionality. Double-check the orientation of decals and panels to match the diagrams. Over-tightening screws may strip threads, so apply moderate force. Ignoring the recommended assembly order can lead to complications. Lastly, never skip steps or assume knowledge beyond what’s provided. Always refer to the included schematics for accurate placement and alignment.

Operating R2D2

Power up your R2D2 using the included batteries or AC adapter. Use the remote control for basic commands like moving, beeping, and activating interactive features. Follow the manual for advanced settings and troubleshooting tips to ensure smooth operation. Always refer to the quick command guide for effortless control of your droid’s pre-programmed functions and movements.

4.1 Basic Commands and Controls

Mastering R2D2’s basic commands ensures smooth operation. Use the remote control to navigate forward, backward, and rotate. Press the button to activate beeps and lights. For movement, use the directional pad, while the center button triggers sounds. Ensure the droid is on a flat surface for stable operation. Refer to the quick command guide for easy access to these functions. Always turn off R2D2 when not in use to conserve battery life. Follow the manual for additional tips on optimizing performance and troubleshooting common issues during operation.

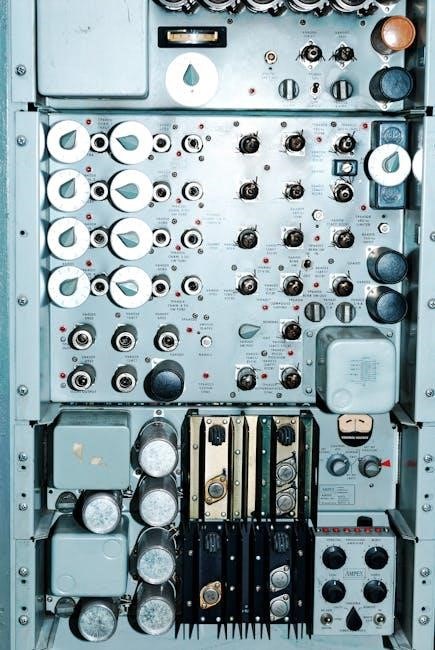

4.2 Advanced Features and Settings

Explore R2D2’s advanced features for enhanced functionality. Use the companion app to access custom settings, such as adjustable movement speeds and sound volumes. Activate interactive modes like “Movie Simulation” for authentic Star Wars experiences. Program sequences of commands for complex tasks. Adjust LED light intensity and sound effects to personalize your droid. Utilize the remote control’s special commands for unique interactions. Refer to the manual for detailed instructions on unlocking these features and optimizing your R2D2 for advanced operation.

Customization and Modifications

Unleash your creativity with R2D2! Personalize its appearance with custom paints and decals. Explore internal modifications for enhanced functionality and unique features to make it truly yours.

5.1 Painting and Cosmetic Customization

Personalize your R2D2 with a fresh coat of paint or decals for a unique look. Use high-quality acrylic paints designed for plastics and apply thin, even layers. Allow each coat to dry fully before adding additional details. For a weathered appearance, lightly sand surfaces and apply washes to recesses. To protect your work, finish with a clear sealant. Always follow safety precautions and work in a well-ventilated area. Refer to the official manual for specific guidance on maintaining authenticity while adding your personal touch.

For intricate designs, use stencils or masking tape to achieve sharp, clean lines. Experiment with metallic finishes for a polished look or matte shades for a battle-worn aesthetic. Decals can also be applied to replicate screen-accurate details. Remember to test paints on a small, inconspicuous area first to ensure compatibility. With patience and creativity, your R2D2 will stand out as a one-of-a-kind droid.

5.2 Internal Modifications for Enhanced Functionality

Enhance your R2D2’s capabilities by modifying its internal components. Install LED lights for illuminated panels or add sound kits to replicate iconic beeps and boops. For advanced users, integrate a programmable microcontroller to enable custom commands and movements. Improve mobility by upgrading the wheels or adding stabilization systems. Ensure all modifications align with the droid’s original design to maintain authenticity. Always consult the manual for compatibility and safety guidelines before making internal changes. These upgrades can transform your R2D2 into a highly functional and interactive companion.

Consider adding sensors for obstacle detection or app-controlled features for remote operation. For a more immersive experience, incorporate motion-activated responses or adjustable speed settings. Remember to test modifications thoroughly to avoid malfunctions. Explore online tutorials for detailed step-by-step instructions tailored to your R2D2 model. With careful planning and execution, these internal modifications will elevate your droid’s performance and functionality.

Maintenance and Repair

Regularly clean R2D2’s exterior and internal components to ensure optimal performance. Check battery levels and connections. Lubricate moving parts and inspect for wear. Consult the manual for troubleshooting common issues and repair guidelines to maintain functionality and longevity.

6.1 Routine Maintenance Tips

Regular maintenance is essential to keep R2D2 functioning optimally; Clean the exterior with a soft cloth to remove dirt and debris. Check and tighten loose screws or connections. Lubricate moving parts to prevent friction and wear. Inspect battery terminals for corrosion and ensure proper charging. Refer to the manual for specific guidelines on cleaning internal components and updating software. Avoid exposing R2D2 to moisture or extreme temperatures. Store in a dry, cool place when not in use. Regularly check for firmware updates to enhance performance and security.

6.2 Troubleshooting Common Issues

If R2D2 experiences functionality issues, start by checking connections and ensuring all parts are securely assembled. Loose screws or misaligned components can cause malfunctions. If the droid does not power on, verify battery installation and charging. For faulty lights or sounds, consult the manual for reset procedures. Clean sensors regularly to avoid obstruction. If issues persist, refer to the troubleshooting section in the manual or contact customer support for assistance. Always follow safety guidelines when diagnosing and repairing your R2D2 to ensure optimal performance and longevity.

Safety Precautions

Ensure all small parts are kept away from children under 3 to avoid choking hazards. Read instructions carefully before assembly and operation. Avoid over-tightening components.

7.1 General Safety Warnings

Ensure all small parts are kept away from children under 3 to avoid choking hazards. Read instructions carefully before assembly and operation. Avoid over-tightening components. Handle electrical parts with care to prevent damage or electrical shock. Keep the droid away from water and extreme temperatures. Follow all safety guidelines to ensure safe and enjoyable use of your R2-D2 model. Properly store small components to prevent loss or accidental ingestion. Always supervise children during assembly and operation. Adhere to these precautions to avoid accidents and maintain the integrity of your R2-D2 unit.

7.2 Operating Environment and Storage Guidelines

To ensure optimal performance and longevity, operate your R2-D2 model in a stable, dry environment; Avoid direct sunlight, extreme temperatures, and humidity. Store the droid in a cool, clean space away from pets and children under 3. After assembly, place loose parts in sealed bags to prevent loss. Regularly inspect for dust or debris, especially in moving components. Use a soft cloth to clean surfaces. Store the model upright to maintain balance and prevent damage; Follow these guidelines to preserve the condition and functionality of your R2-D2 unit for years of enjoyment.

Congratulations! You’ve successfully assembled and prepared your R2-D2 model. This manual has guided you through assembly, operation, and maintenance. Enjoy your droid and explore its features confidently!

8.1 Final Checklist for Successful Assembly and Operation

- Confirm all components are included and properly assembled.

- Ensure the dome, body, and legs are securely connected.

- Verify batteries are correctly inserted and the power switch is functional.

- Test all movement and sound features to ensure proper operation.

- Review the instruction manual for any final adjustments or settings.

- Double-check that all small parts are safely secured to avoid loss.

- Ensure compliance with safety precautions and usage guidelines.

Once these steps are completed, your R2-D2 is ready for operation. Enjoy your fully functional and accurately assembled droid!

8.2 Encouragement for Further Exploration and Customization

Congratulations on successfully assembling and operating your R2-D2! Now, explore the endless possibilities for customization to make your droid truly unique. Consider adding custom decals, painting, or modifying internal components for enhanced functionality. Research online communities or LEGO Star Wars forums for inspiration and tips. Don’t hesitate to experiment—every modification is an opportunity to personalize your R2-D2 further. Remember to always follow safety guidelines and the manual’s instructions when making changes. Embrace creativity and enjoy the journey of making your R2-D2 stand out!