Torque tables provide essential specifications for Honda engine components, ensuring proper tightening and preventing damage. They guide mechanics through precise bolt tightening, crucial for engine longevity and performance.

Overview of Torque Specifications

Torque specifications are critical for ensuring proper engine assembly and maintenance. They provide precise values for tightening bolts and fasteners, preventing damage from over- or under-tightening. For Honda engines, these specifications vary by component, such as cylinder head bolts, connecting rods, and engine block bolts. Values are typically measured in Nm (Newton-meters) and must be followed closely to maintain engine integrity. For example, the A18A1 engine specifies torque values like 80 mm for piston diameter and 0.12-0.18 Nm for connecting rod bolts. Adhering to these guidelines ensures optimal engine performance, prevents leaks, and avoids costly repairs. Always consult official Honda manuals or reliable sources for accurate torque charts.

Importance of Torque in Engine Maintenance

Proper torque application is vital for maintaining engine reliability and longevity. Incorrect torque values can lead to engine damage, leaks, or premature wear. For Honda engines, precise torque ensures that components like cylinder heads, crankshafts, and camshafts are securely fastened. Over-tightening can warp surfaces, while under-tightening may cause parts to loosen, leading to catastrophic failures. Using torque tables helps prevent these issues, ensuring all fasteners are within safe limits; This maintains engine performance, fuel efficiency, and reduces repair costs. Regularly referencing torque specifications is essential for both professional mechanics and DIY enthusiasts to ensure accurate and safe engine maintenance practices.

Where to Find Torque Tables for Honda Motors

Torque tables for Honda motors are available in official Honda service manuals, online databases, and reputable automotive forums. These resources provide precise specifications for various engine components.

Official Honda Manuals and Resources

Honda provides comprehensive torque tables and specifications through official service manuals and resources. These manuals are available on Honda’s official website or through authorized dealers. They include detailed torque values for engine components like cylinder heads, engine blocks, and bolts. Additionally, Honda publishes a torque specification guide for various engine models, ensuring accurate and reliable data for mechanics. These resources are updated regularly to reflect the latest engineering standards and are essential for maintaining Honda engines correctly. By referencing these official materials, professionals can ensure precise torque applications, preventing damage and optimizing engine performance.

Reliable Online Sources for Torque Charts

Reliable online sources provide easy access to Honda engine torque charts. Websites like DENSO and Fel-Pro offer detailed torque specifications for various engine components. These sources include charts for glow plugs, cylinder head bolts, and engine gaskets. For example, DENSO recommends 8-10 Nm for M8 Y-type glow plugs, while Fel-Pro provides consistent torque values for gaskets. Online forums and automotive repair databases also offer downloadable PDFs, such as the Tabla de Torque para Motores Honda, ensuring accurate data for engine maintenance. These resources are frequently updated and align with OEM standards, making them indispensable for mechanics and DIY enthusiasts.

Understanding Torque Specifications

Torque specifications outline precise values for engine components, ensuring proper assembly and performance. They include bolt torque, gasket seals, and tightening sequences for Honda engines, preventing damage and ensuring reliability.

Key Components of Torque Tables

Torque tables for Honda engines detail critical specifications, including bolt sizes, torque values, and tightening sequences. They cover various components like cylinder heads, engine blocks, and intake manifolds. These tables also specify the correct order of tightening to ensure even stress distribution, preventing warping or damage. Additionally, they provide information on gasket types and lubrication requirements. Accurate torque values are given in Nm or ft-lbs, and some tables include angular tightening specifications. Proper adherence to these guidelines ensures optimal engine performance, longevity, and reliability, making torque tables indispensable for mechanics and technicians working on Honda engines.

How to Read and Interpret Torque Charts

Reading torque charts for Honda engines requires understanding the specified values and sequences. Identify the component, such as cylinder head or engine block bolts, and locate the corresponding torque value. Ensure the bolt size matches the chart to avoid errors. Pay attention to tightening sequences, often indicated by diagrams or numbers, to ensure even stress distribution. Use a torque wrench calibrated to the chart’s units (Nm or ft-lbs). Some charts include angular tightening specifications, requiring bolts to be turned beyond the initial torque value. Always follow the manufacturer’s guidelines to prevent over- or under-tightening, which can lead to engine damage. Proper interpretation ensures accuracy and safety during engine assembly or maintenance.

Applying Torque in Practice

Applying torque involves using a torque wrench to tighten bolts to specified values, following sequences to ensure even stress distribution and prevent damage to engine components.

Tightening Sequences for Engine Components

Tightening sequences are critical for ensuring even stress distribution across engine components. For Honda engines, specific patterns are recommended, such as starting from the center and working outward. This method prevents warping and ensures proper sealing of surfaces like cylinder heads. For example, cylinder head bolts are typically tightened in a star pattern, applying torque in increments to avoid over-stressing. Similar sequences apply to engine blocks and valve train components. Adhering to these sequences is essential for maintaining engine integrity and performance. Neglecting proper tightening order can lead to uneven wear, leaks, or even engine failure. Always consult the torque table for precise guidance on tightening sequences for your specific Honda engine model.

Common Bolts and Their Torque Values

Common bolts in Honda engines include cylinder head bolts, main bearing bolts, and connecting rod bolts. Their torque values vary by engine model but typically range from 30 to 80 Nm. For example, M8 bolts often require 20-30 Nm, while M10 bolts may need 40-50 Nm. New plugs and gaskets usually require higher torque than used ones. Specific bolts, like the M8 Y-type glow plug, may need 8-10 Nm. Always refer to the torque table for precise values, as over-torquing can damage threads or components. Proper torque ensures optimal engine performance and longevity. Consulting official Honda manuals or reliable sources is essential for accurate specifications.

Special Considerations

Special considerations include torque adjustments for modified engines and temperature impacts on settings. Always use official Honda manuals for accurate specifications and reliable results in engine maintenance.

Torque Adjustments for Modified Engines

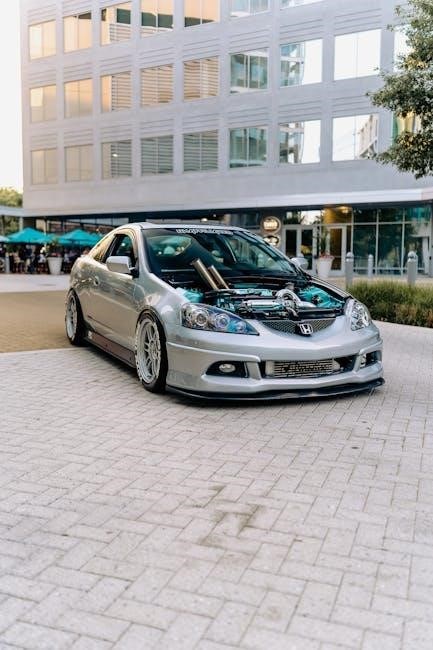

For modified Honda engines, torque specifications may vary due to altered components or performance upgrades. It’s crucial to consult updated torque charts or manufacturer guidelines to ensure proper adjustments. Modified engines, such as those with aftermarket parts or engine swaps, require custom torque values to maintain reliability and performance. Always reference official Honda manuals or reliable sources for accurate data. Improper adjustments can lead to engine damage or reduced efficiency. Mechanics often recommend specific torque settings based on the extent of modifications, ensuring optimal results for enhanced power or durability. Regular inspections and adjustments are essential to uphold the integrity of the engine and its components.

Impact of Temperature on Torque Settings

Temperature significantly influences torque settings for Honda engines, as material properties change with heat. At elevated temperatures, engine components like aluminum and steel expand, altering torque requirements. High heat can reduce friction, potentially lowering torque needs, but extreme temperatures may cause parts to loosen over time. Conversely, in cold conditions, materials contract, possibly requiring increased torque for proper sealing. Always consult torque tables specific to operating temperatures to avoid over- or under-tightening, which can lead to engine damage. Proper adjustment ensures optimal performance and prevents issues like head warping or gasket failure. Using a torque wrench and following temperature-specific guidelines is essential for maintaining engine integrity and longevity.

Troubleshooting Torque-Related Issues

Identify and address torque-related problems by checking for loose bolts, uneven tightening, or damaged threads. Use a torque wrench and consult charts to prevent over- or under-tightening, ensuring engine stability and performance.

Identifying and Addressing Over-Torquing

Over-torquing can cause bolt stretching, thread damage, or even engine component failure. To identify it, look for signs like stripped threads or uneven bolt seating. If over-torquing occurs, immediately cease operations and replace damaged bolts. Consult torque charts for correct specifications and ensure all fasteners are tightened in the recommended sequence. Using a torque wrench accurately helps prevent this issue. In severe cases, professional intervention may be required to assess and repair damage. Always refer to Honda’s official guidelines for specific torque values and procedures to maintain engine integrity and performance. Regular training on torque application is essential for mechanics to avoid such problems.

Consequences of Under-Torquing

Under-torquing can lead to loose connections, resulting in engine leaks, excessive wear, and potential failure of critical components. Insufficient torque may cause bolts to vibrate loose over time, leading to premature wear on engine parts. This can also create uneven stress distribution, potentially causing cracks or damage to cylinder heads, blocks, or other components. In severe cases, under-torquing can result in catastrophic engine failure, especially under high-stress conditions like acceleration or towing. Regularly consulting torque charts and using a torque wrench ensures proper tightening, preventing these issues. Always adhere to Honda’s specifications to maintain engine performance and longevity.

Proper torque application is vital for engine longevity. Always consult Honda’s specifications to ensure accurate and safe tightening of components.

Best Practices for Using Torque Tables

Using torque tables effectively involves adhering to Honda’s specifications and proper techniques. Always reference the official Honda manual or reliable sources for accurate values. Ensure your torque wrench is calibrated and use the correct socket size to avoid errors. Follow recommended tightening sequences to prevent uneven stress on components. Double-check torque values for bolts of different sizes or materials. Maintain a record of torque applications for future reference. Be aware of modifications that may require adjusted torque settings. Finally, consult a professional if unsure, as over- or under-tightening can lead to engine damage. Proper adherence ensures reliability and longevity of your Honda engine.

Future Developments in Torque Specifications

Future torque specifications for Honda engines are expected to evolve with advancements in material science and engine design. New materials like lightweight alloys and composite components may require revised torque values to maintain durability. Honda is likely to adopt more precise, real-time torque monitoring systems, integrating sensors into engines for dynamic adjustments. Electric and hybrid powertrains may introduce new torque standards, optimizing efficiency and performance. Additionally, advancements in software and AI could enable predictive torque calculations, reducing maintenance needs. As engines become more sophisticated, torque tables will adapt to ensure compatibility with emerging technologies, enhancing overall engine reliability and operational efficiency for future Honda models.